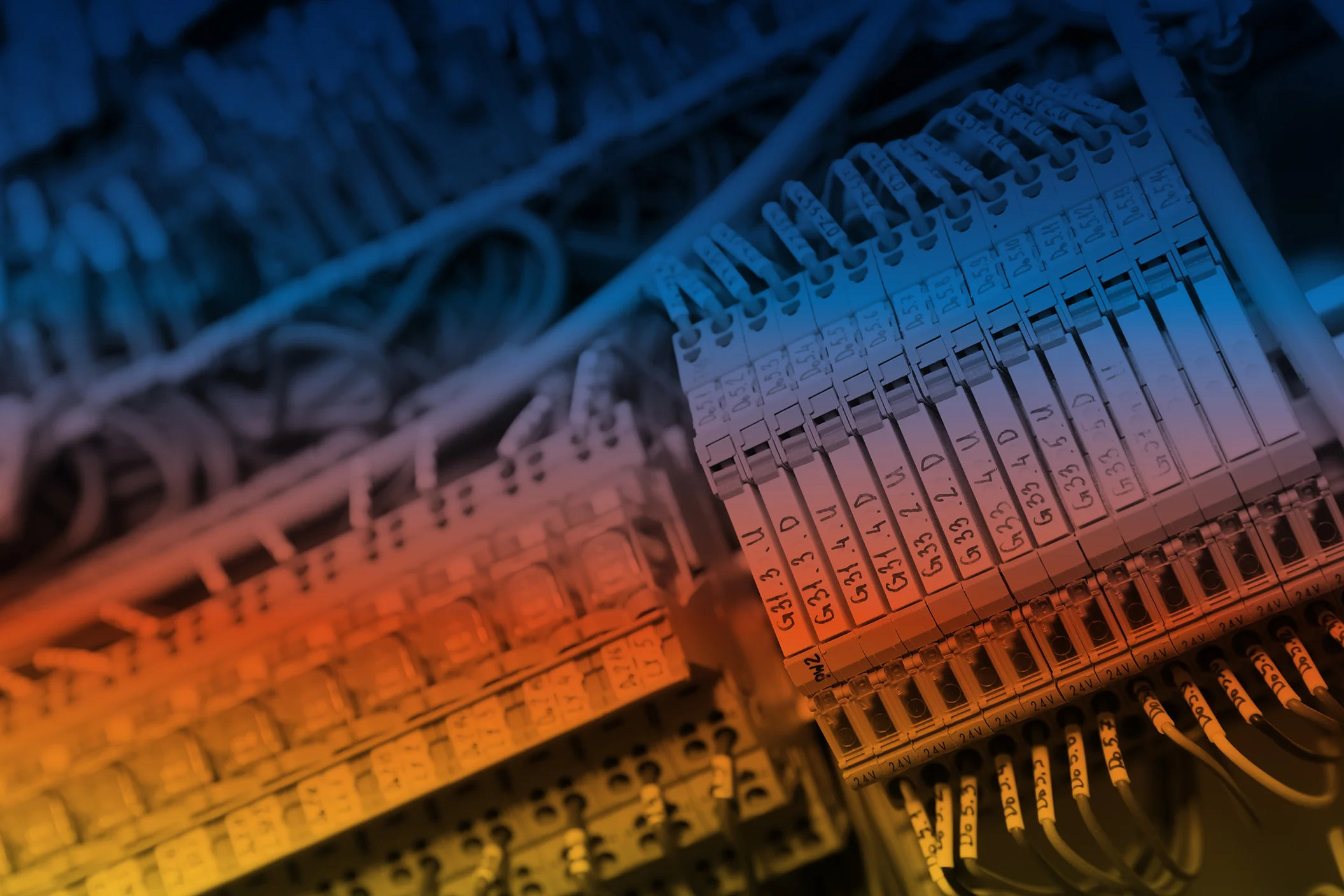

Electrical Thermal Imaging Surveys

Thermal imaging surveys are useful in a range of applications, including checking electrical systems. They allow you to identify flaws and issues, create a predictive maintenance plan, and verify the performance of the systems.

You can rest assured that thermographic surveys are non-invasive, so you don’t need to knock down a wall to identify an electrical fault, a problem with equipment or a loose connection, for instance. They're also cost-efficient and BREEAM-compliant.

What Does an Electrical Thermal Scan Help with?

Thermography can help identify any potential failures, including:

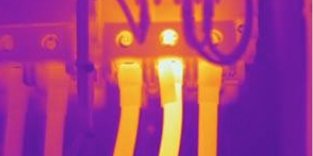

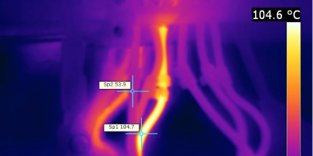

Poor Connections - Thermal imaging can detect the problems of poor connection early, the same goes for instances where the cabinets may be overloaded.

Electrical Leakage - Thermal Surveys are able to find any evidence of a leak happening, in time for you to put a stop to it, preventing possible harm to you and others.

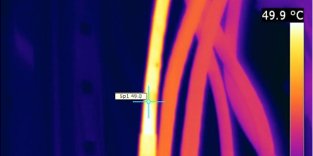

Insulator Defects - Using thermography you can be protected from the dangerous parts of electricity, ensuring insulators are working properly.

Internal Fuse Damage - Helps to prevent the risk of a fuse blowing, from an extensive current flowing through it.

Oxidation of High Voltage Switches - Prevents resistance between connectors, finding the problem before it occurs.

Questions About Electrical Thermography Surveys Answered

-

Our surveys are carried out by a team of Level II certified engineers. These experts can perform inspections as part of your ongoing maintenance plan or for individual assessments tailored to your needs.

-

Before conducting the assessment, our engineers may visit your site to gather essential information. As part of the process, you’ll receive:

A detailed risk assessment and method statements.

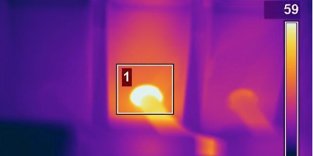

A comprehensive report of findings, including both thermal and digital photos of key components.

Reports tailored to meet insurance standards.

-

We use advanced FLIR thermal imaging cameras to inspect electrical systems and components of all shapes and sizes. This technology allows for precise detection of issues and ensures comprehensive coverage of your installations.

-

Thermographic inspections are a fast and non-disruptive way to identify electrical issues to precise safety standards. They allow defects to be detected before equipment fails, helping to minimise costs, reduce downtime, and improve safety.

-

Thermal imaging helps identify potential faults in electrical systems before they lead to breakdowns, equipment failures, or even fires. These inspections ensure that your systems are operating safely and efficiently, reducing the risk of costly disruptions.

With detailed reporting and the expertise of certified engineers, these surveys ensure your electrical systems are running safely and performing as they should. This proactive approach prevents unexpected failures and ensures compliance with safety standards.

-

By spotting faults before they occur, infrared inspections help extend the lifecycle of your electrical equipment and minimise repair or replacement expenses. They can also identify energy savings, making them a cost-effective solution for businesses and industries.

Contact Us For an Electrical Thermal Survey

We're on hand to help with anything you require, so get in touch on 01234 219421 to discuss your project with us; alternatively, send us a message to support@thermascan.co.uk and we’ll answer all your questions.

Here at Thermascan Ltd all of our engineers hold certified level 2 qualifications in thermography with the experience of test and inspection.